The advantages and disadvantages of CNC Machine

Half a century ago, machinists were always responsible for crafting every single piece to perfection. These skills are still needed, but when it comes to producing the same piece at high volume and high precision, computerized machines are vastly superior. That’s where Computer Numerical Controlled (CNC) machining comes in.

There are many advantages to utilizing a CNC machine compared to other forms of manufacturing and production.

Advantages

1. Continuous Use: Unlike manual labor, CNC machinery (excluding any malfunction or maintenance issue) can work continuously over any period of time without a break. This greatly increases productivity and efficiency.

2. Consistency, Precision, and Redundancy: With computer software, the design of any given product only needs to be programmed once. The CNC machine can then perfectly replicate that design, for any order quantity.

3. Low Skill Requirement: CNC machine operators require little training and skill when compared to manual machine operators.

4. Fewer Personnel: Because computer software controls the machinery, fewer technicians are needed for operation and oversight, cutting overall expenses.

5. Flexibility: The software can be reprogrammed quickly and easily to produce different parts, allowing operations to keep up with shifting customer demands.

6. Capability: This technology uses computer precision to go beyond the limitations of manual capabilities. More complex and intricate operations are possible with CNC machining.

Disadvantages

1. Cost: CNC machines are more expensive and require a greater initial investment than machines that can be operated manually. However, as this technology becomes the standard, supply is increasing resulting in costs gradually decreasing.

2. Skills Loss: As the demand for manual machine operators decreases, fewer and fewer new students adopt those skills. This could eventually lead to the complete loss of long-preserved skills.

3. Unemployment: Automation decreases the need for manpower, and fewer laborers are hired. That said, the need is now shifting to software engineers and mechanical engineers, and education and training will have to adjust to meet that need.

Overall, the advantages of CNC machining far outweigh the disadvantages. While other manufacturing processes and equipment each have their own advantages, the benefits of CNC machines tend to outweigh any competition because of how efficient these machines are.

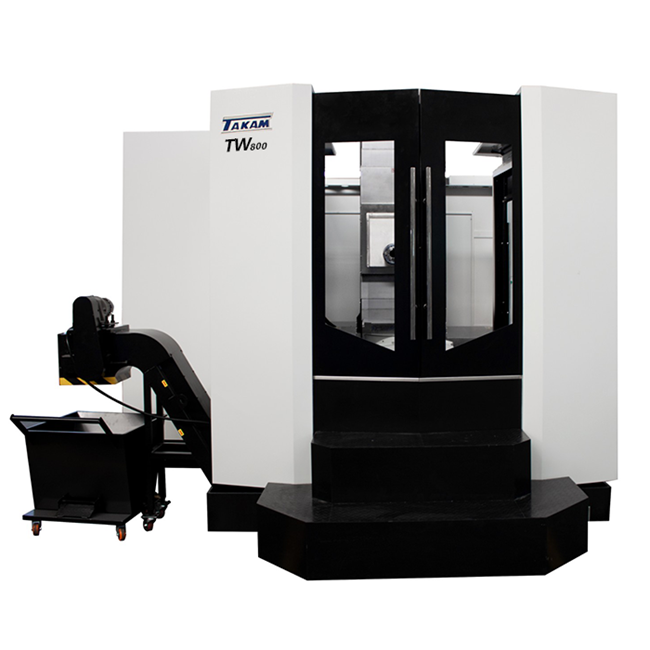

As with the advent of any new technology, TAKAM must anticipate shifts and adjustments to meet new challenges. Ours machining styles including CNC Vertical Machine Center, CNC Horizontal Machine Center, Double Column Machine Center, CNC Lathe etc. Please browse our Website: www.TAKAM.com to get more information about our specific equipment. We have the capability, capacity, efficiency and expertise to meet high demands. We are looking forward your connection.

简体中文

简体中文