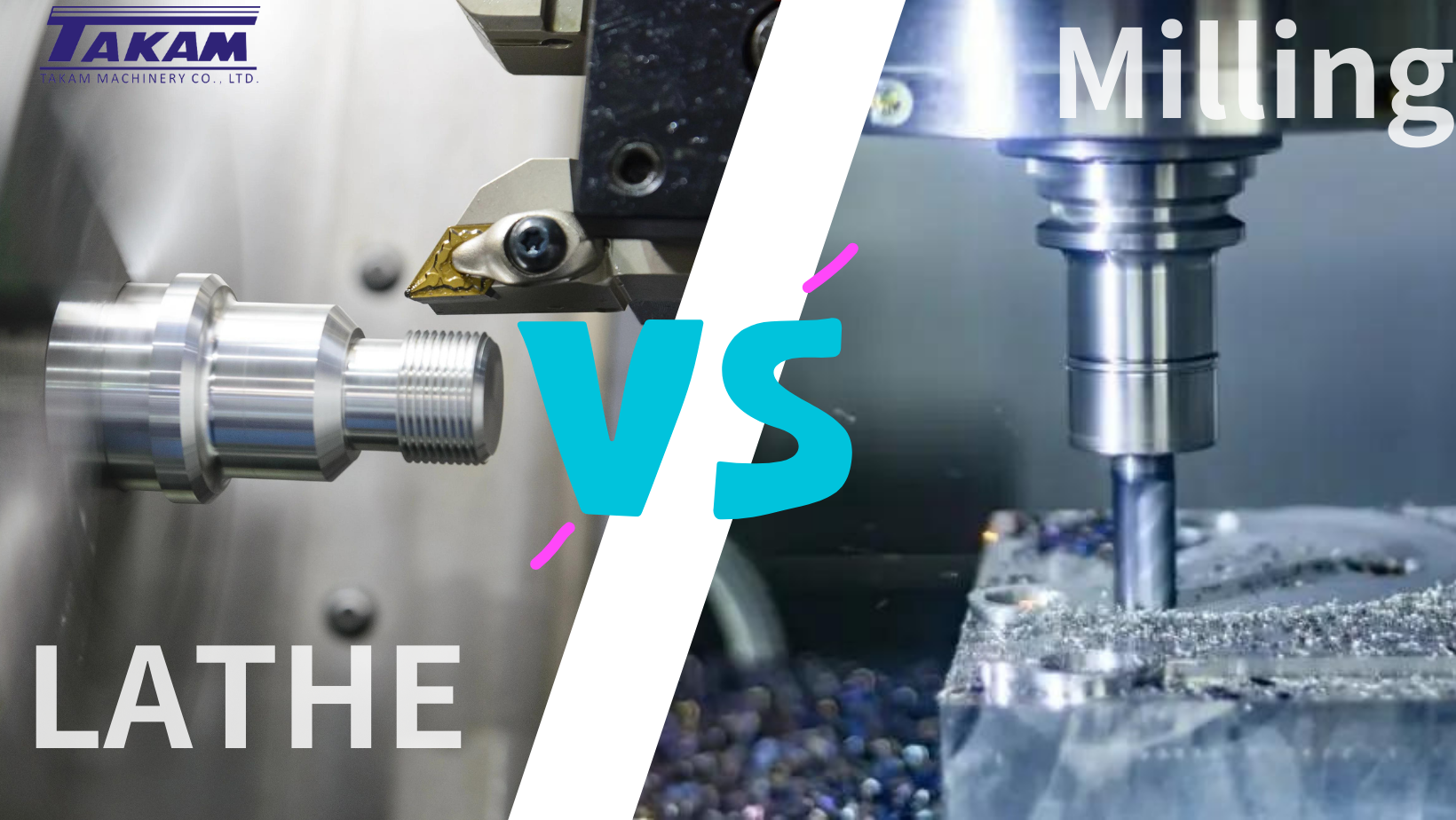

Lathe Machine vs Mill

A lathe machine and a milling machine are both tools used for machining, but they serve different purposes and operate in distinct ways. Here's an overview of each:

Lathe Machine:

Purpose: A lathe is primarily used for turning and shaping cylindrical workpieces. It rotates the workpiece on its axis and uses cutting tools to remove material and create a symmetrical object.

Operation: The workpiece is secured on the spindle, and the cutting tool is brought into contact with the rotating workpiece to remove material. Lathes are commonly used for tasks such as facing, turning, drilling, and threading.

Applications:

Creating cylindrical shapes like shafts and rods.

Turning operations for creating symmetrical parts.

Thread cutting and facing operations.

Types:

Engine lathe: General-purpose lathe for a variety of tasks.

CNC lathe: Computer Numerical Control allows for automated precision.

Mill Machine:

Purpose: A milling machine is used for cutting or shaping solid materials. It removes material using rotary cutters, which move along multiple axes. This results in a variety of shapes and sizes being created on the workpiece.

Operation: The workpiece is fixed to the machine bed, and cutting tools remove material by moving across it. Milling machines can perform a range of operations, including face milling, end milling, and peripheral milling.

Applications:

Creating flat or contoured surfaces.

Drilling, boring, and slotting.

Precision cutting and shaping.

Types:

Vertical milling machine: The spindle axis is vertical.

Horizontal milling machine: The spindle axis is horizontal.

CNC milling machine: Computer Numerical Control for automated precision.

Key Differences:

Operation: Lathes rotate the workpiece, while milling machines keep the workpiece stationary, moving the cutting tool.

Primary Function: Lathes are best for creating cylindrical shapes, while milling machines are versatile for creating a wide range of shapes and surfaces.

Tool Movement: Lathes have a single-point cutting tool that moves parallel to the axis of rotation, while milling machines have multiple cutting tools that move on multiple axes.

Resulting Shapes: Lathes produce cylindrical and conical shapes, while milling machines can produce flat, curved, or irregular surfaces.

Both lathe machines and milling machines are essential tools in machining and manufacturing processes, and the choice between them depends on the specific requirements of the task at hand. Often, a combination of both machines is used in a machining workshop to achieve a broader range of operations.

简体中文

简体中文